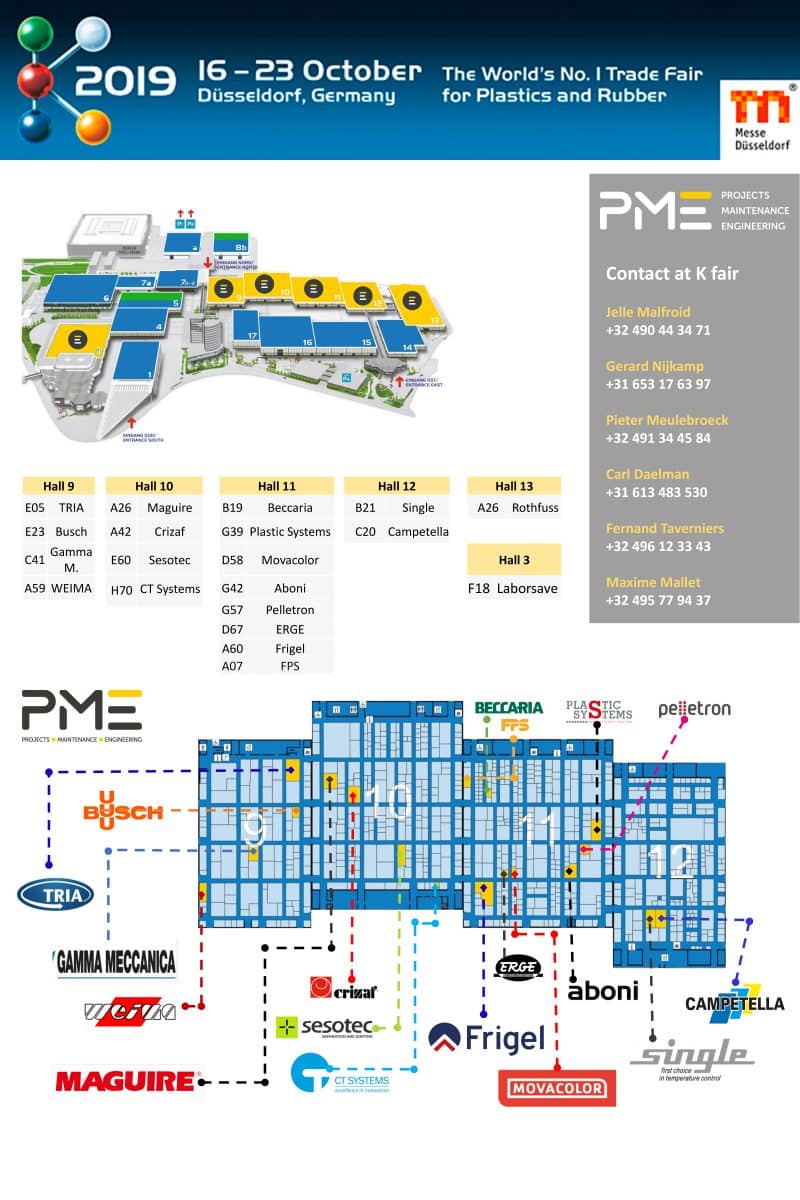

TRIA – E05

BUSCH – E23

GAMMA MECCANICA – C41

WEIMA – A59

MAGUIRE – A26

CRIZAF – A42

SESOTEC – E60

CT Systems – H70

FRIGEL – A60

ERGE – D67

MOVACOLOR – D58

Beccaria – B19

ABONI – G42

Pelletron – G57

Plastic Systems – G39

Single – B21

Campetella – C20

FPS Services – A07

Highlights at K-messe

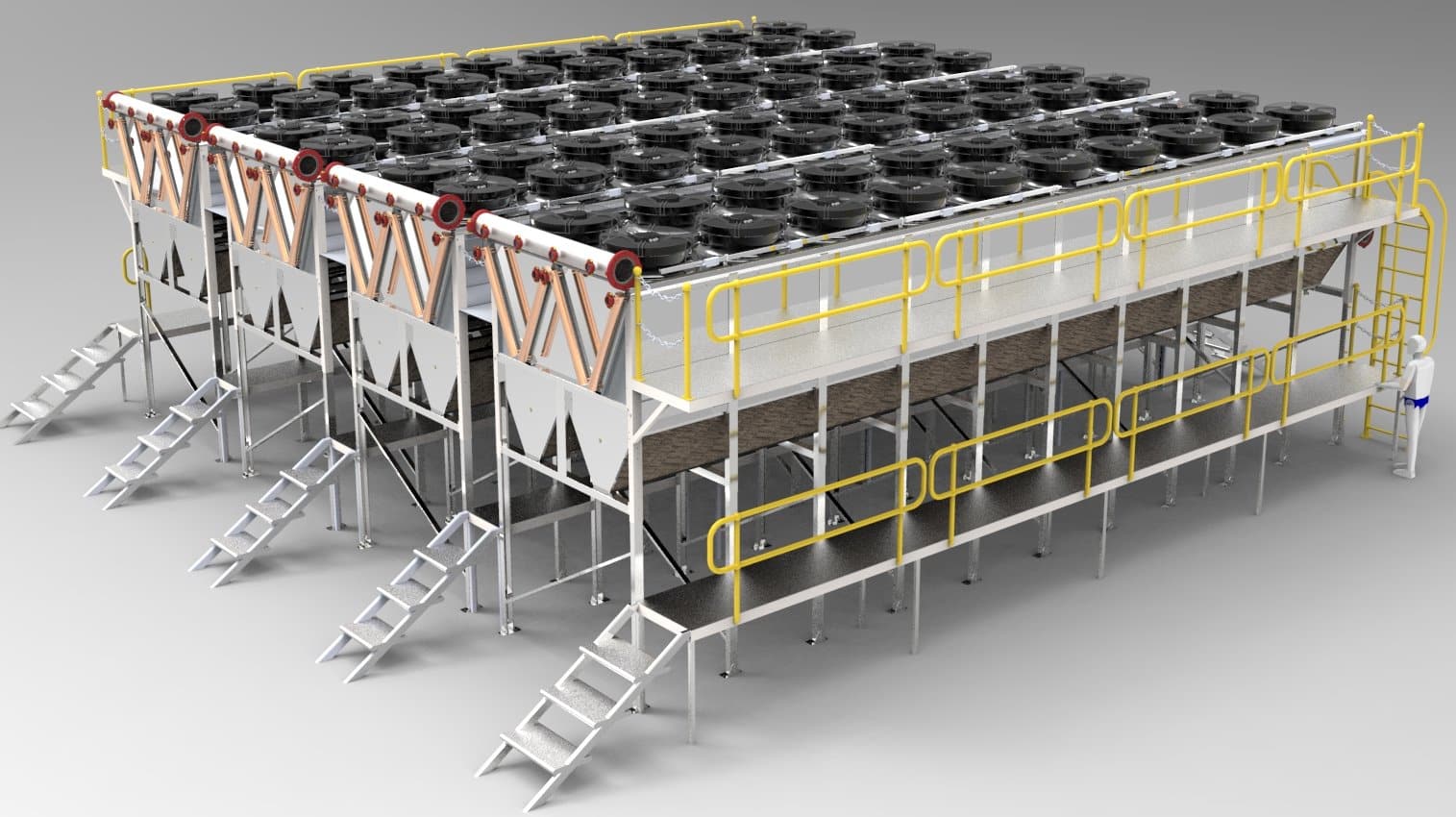

FRIGEL : HALL 11 – BOOTH A60

- Microgel™ – TCUs with Booster Pumps and Integrated Portable Chiller

- 100% new digital technology and touch screen control.

- Cooling cycle time reductions (up to 50%!)

- Saves up to 95% water,

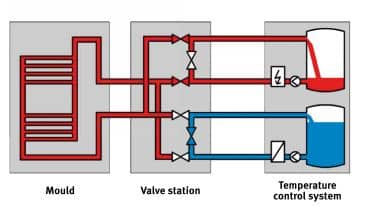

SINGLE : HALL 12 – BOOTH B21

SINGLE ATT – Advantages

- prolongs the holding pressure

- helps reduce injection pressure and clamping force

- decreases internal stress during compression moulding

- enhances surface properties such as self-cleaning or antireflection

- reduces the risk of warpage caused by shrinkage

- cuts cycle times.

MOVACOLOR: HALL 11 – BOOTH D58

- The MCNexus optometric dosing system

- enables highly accurate, pellet by pellet dosing

- specially developed for micro injection molding

- or micro extrusion applications.

CAMPETELLA: HALL 12 – BOOTH C20

- Carbon fiber robot structure

- Less than 2.5 seconds

- Side entry robots

- Complex IML solutions

MAGUIRE: HALL 12 BOOTH A26

Clear cut return on investment through energy: The Maguire ULTRA

- Uses drastically less energy than comparable dryers.

- Paying for itself just on energy savings multiple times over

- “With costs so low, it’s almost free”

- the ULTRA Low Energy Dryer has environmental savings of 54,120kW per year.

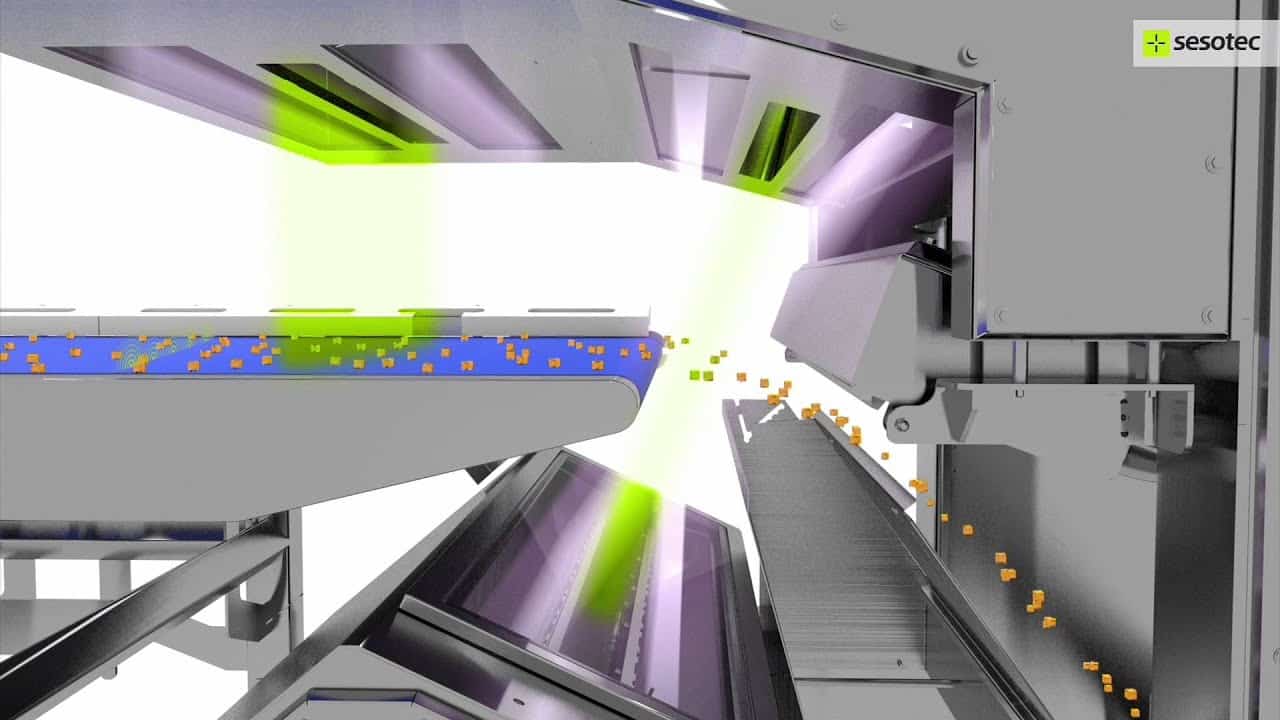

SESOTEC : HALL 10 – BOOTH E60

PURITY MATTERS

- Save energy and be able to use cheaper plastics

- The purity of the material is crucial to efficient recycling.

- efficiently separate into homogeneous fractions by color and type material

Advantage of metal detectors

- Less downtime

- Less chance of damage to machinery by tiny metals

- Optimum protection againt interruptions to production

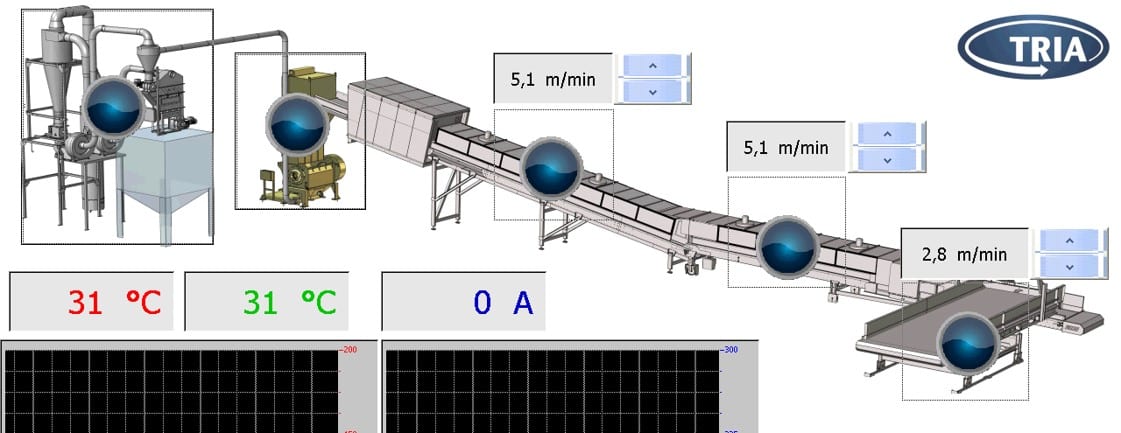

TRIA: HALL 9 – BOOTH E05

SMART GRINDER: 4.0 AND SUSTAINABILITY

- Speed regulation +46 m/min increased

- Noise reduced of 4dB

- Maintenance without having to tilt the traction unit

- Only 5% of installed power used for dry operation

- Only 30% of power used for grinding

- sequential automatic shutdown

PLASTIC SYSTEMS: HALL 11 – BOOTH G39

HOT-AIR DRYERS & SYSTEMS

- dry non-hygroscopic plastic. granules

- Stainless-steel hoppers

- display for settings and viewing alarms

- Daily/weekly timer.

- Hinged covers to install hopper loaders